Magnetic shielding – Theory and practice

What is a magnetic field?

A magnetic field is a physical phenomenon produced by the displacement of electric charges and revealed by magnetic materials. There are many different sources of magnetic fields, such as the Earth, a motor, a transformer or a simple magnet.

The magnetic field can be measured using a Gaussmeter, a magnetometer or a coil connected to an oscilloscope. The magnetic field is involved in many electromechanical applications.

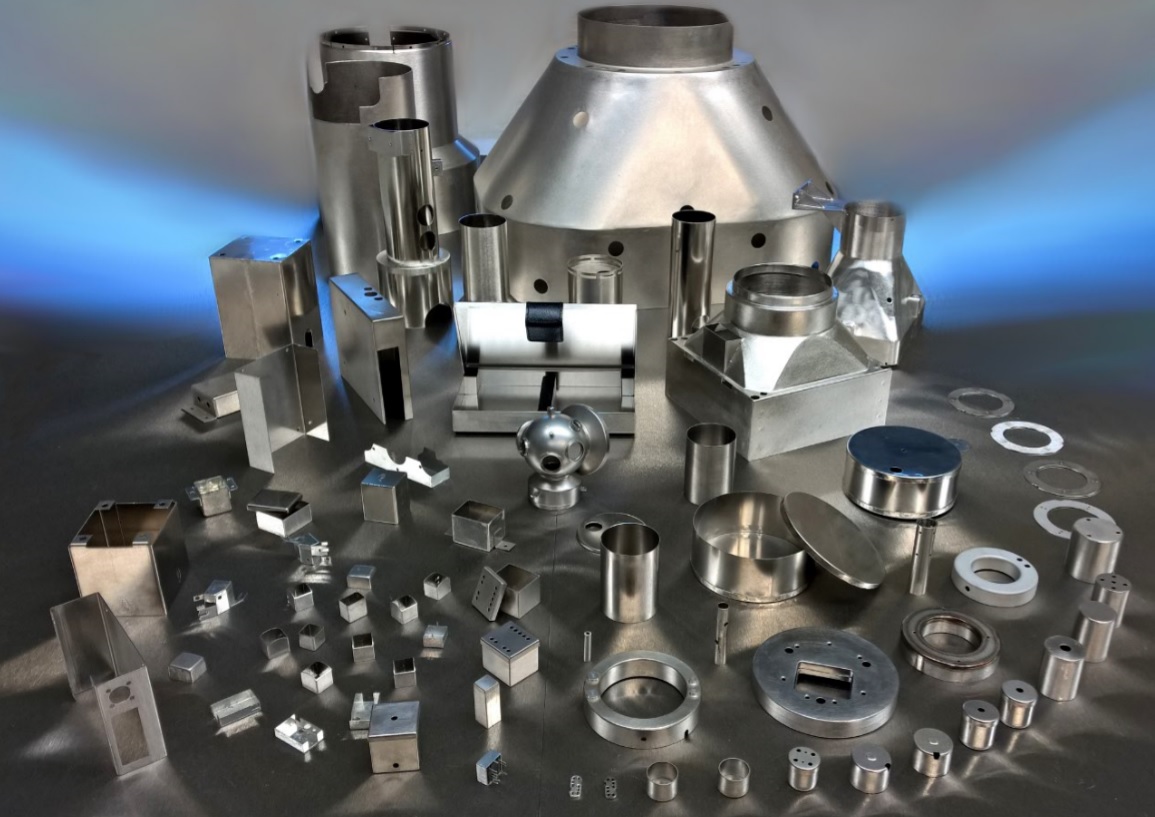

In some cases, the magnetic field interferes with other equipment and can become problematic. With numerous studies and designs to its credit, Soudupin will provide the most appropriate solution for magnetic fields ranging from a few nano Tesla to several hundred Gauss.

Why use magnetic shielding?

Low-frequency magnetic shielding is used to protect devices sensitive to magnetic interference, such as medical equipment, research instruments, sensors and electronic circuits, by minimizing the disruptive effects of surrounding magnetic fields. This results in more accurate measurements and reduces distortions or errors caused by magnetic interference.

What is magnetic shielding?

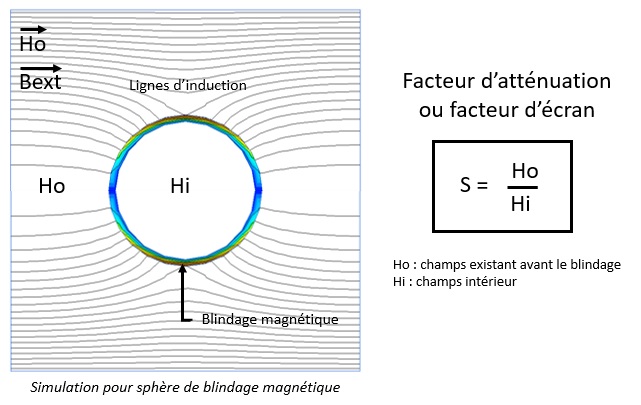

The purpose of magnetic shielding is to attenuate a magnetic field in a given space by “attracting” the field lines with a magnetic material.

Low-frequency magnetic shielding is used to attenuate static or low-frequency (<1kHz) magnetic fields, and is our core business.

How does it work?

Our magnetic shields are made from ferromagnetic alloys. These materials, based on Iron, Nickel, Copper and Molybdenum, “attract” the magnetic field and “focus” the field lines along their surface.

The attenuation of magnetic shielding depends primarily on the permeability of the material used. The higher the permeability of the material used, the better the attenuation. The permeability of ferromagnetic materials varies non-linearly as a function of the magnetic excitation H. It rises to a maximum, the so-called maximum permeability, and then falls. In other words, some materials will be preferred for weak fields, others for strong ones.

Design parameters

Materials : The choice of material depends on the characteristics of the magnetic field to be attenuated: its intensity and frequency, as well as the desired attenuation. Mumetal® or Permimphy® is the most widely used material, offering high permeability for weak, medium and strong fields.

Shape / Geometry : Spherical or cylindrical shapes or rounded corners are preferred to sharp edges.

Thickness : Shielding performance increases with material thickness

Successive layers : Shielding performance increases with the number of layers. The space between layers also improves shielding performance.

These are the main considerations when designing magnetic shielding. There are many other factors to consider during manufacture, but these are all within the scope of our expertise, so don’t hesitate to contact us for a solution to your magnetic problems!

Magnetic materials

- Mumetal® / Permimphy® : Ni80FeMo5, high permeability, most widely used

- Supermimphy® : Ni80FeMo5, very high permeability

- Cryophy® / Cryoperm® / A4K® : Ni81FeMo5, high permeability, for magnetic shielding at cryogenic temperatures

- Supra50® : FeNi48, high permeability and high saturation induction

- Supra36® : FeNi36, good permeability, high resistivity

- Pure iron : Good permeability for medium and strong fields, high saturation induction

- Silicon iron: FeSi3, good permeability for medium and high fields, high saturation induction

Heat treatment

This is a crucial step in the manufacturing process of mumetal magnetic shields. The material is heated to between 1100°C and 1150°C for a specific period, followed by slow cooling. This step creates a precise crystalline structure in the material, designed to improve its magnetic permeability.

Thermal annealing aims to reduce the random magnetic moments present in the mumetal structure, thereby lowering the material’s magnetic susceptibility. This improves the material’s attenuation of the external magnetic field, making magnetic shielding more effective.